Food Hose

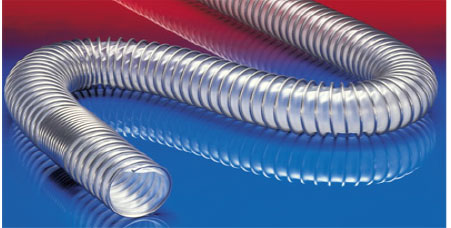

PROTAPE® PUR-C 335 FOOD

-AS FLAT

Screening machine hose and compensator, vibration resistant

Applications:

- food industry, pharmaceutical industry: food, pharmaceutical

- conveying of dry foods e.g. rice, cereals, sugar, milk powder, powders, coffee, tea, grains, flour, frozen foods

- mixer, dryer, packaging machine, bulk-bag (big bag)-charging and discharging, mill

- explosion hazard area

- screening machine/ sifting machine, vibration screening machine, tumbler screening machine, plansifter, windsifter

- bellows, compensators

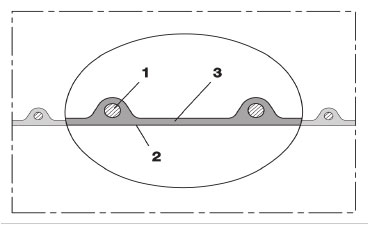

Design, material:

Patented PROTAPE® tape hose

- wall interior and exterior smooth

- wall: permanently antistatic premium ether-polyurethane (Pre-PUR®)

- wall thickness 0.04 inch approximate, wall interior smooth

- grounding wire

Temperature Range:

- -40°F to 195°F

- short time to 255°F

Properties:

- highly flexible

- abrasion-resistant

- vibration resistant

- Food grade wall, complies with: EU-Directive 10/2011 and EC 1935/2004, incl. the latest EU-Directive 2015/174, FDA 21 CFR 177.2600

- odorless and tasteless

- microbe and hydrolysis resistant

- good resistance to oil, gasoline, and chemicals

- very good low temperature flexibility

- permanently antistatic wall: in accordance with ISO 8031 electrical and surface resistance <10⁹ Ω

- in accordance with ATEX 2014/34/EU (1999/92/EC) and German TRGS 727: aspiration of combustible dust (zone 22 inside), for conveying of non-flammable liquids, for use in zone 1 and 2 (gases)

- manufacturing process acc. GMP EC 2023/2006

- conforms to RoHS guideline

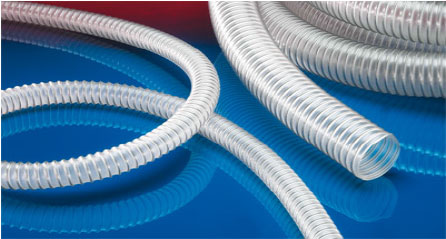

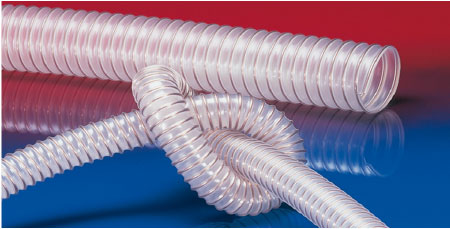

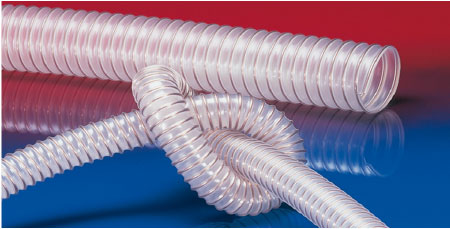

AIRDUC® PUR-INOX 355 FOOD-AS

Antistatic food hose and pharmaceutical hose, heavy duty, stainless steel (INOX)

Applications:

- flexible hose/ ducting for high volume of abrasive powder, bulk material, granulate and for gases

- food industry, pharmaceutical industry: food, pharmaceutical

- conveying of dry foods e.g. rice, cereals, sugar, milk powder, powders, coffee, tea, grains, flour, frozen foods

- vacuum conveying device, vacuum hopper, suction conveyor, dosing system

- pelleting machines/ tablet presses

- mixer, dryer, packaging machine, bulk-bag (big bag)-charging and discharging, mill

- industrial vacuum cleaners, vacuum cleaners

- explosion hazard area

- animal stall, animal shed: feedstuff conveying, feedstuff plant, animal feed transport

Design, material:

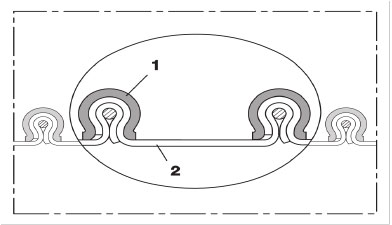

AIRDUC® profile hose

- spring steel wire firmly embedded in the wall, spiral: stainless steel wire (INOX)

- wall: permanently antistatic premium ether-polyurethane (Pre-PUR®)

- wall thickness 0.055 – 0.060 inch approximate

Temperature Range:

- -40°F to 195°F

Properties:

- heavy duty

- highly abrasion resistant

- increased pressure and vacuum resistance

- Approved by an independent testing laboratory for the complete hose acc. to EU-Directive 10/2011 and EC 1935/2004 and the latest EU-Directive 2015/174, food grade polyurethane, complies with: FDA 21 CFR 177.2600

- Approval acc. to EU-Directive 10/2011 (food simulant E) and EC 1935/2004

- odorless and tasteless

- microbe and hydrolysis resistant

- good resistance to oil, gasoline, and chemicals

- very good low temperature flexibility

- permanently antistatic wall: in accordance with ISO 8031 electrical and surface resistance <10⁹ Ω and in accordance with TRGS 727 <2,5*10⁸Ω

- in accordance with ATEX 2014/34/EU (1999/92/EC) and German TRGS 727: pneumatic transport of flammable dusts and bulk materials (Zone 20, 21, 22 inside), aspiration of combustible dusts (Zone 22 inside), for conveying for flammable liquids (inside zone 0, 1, 2), for conveying for non-flammable liquids, for use in zone 1 and 2 (gases), for use in zone 0 (gases)

- manufacturing process acc. GMP EC 2023/2006

- conforms to RoHS guideline

Applications:

- flexible hose/ ducting for gases and for abrasive dust, powder, fibers

- food industry, pharmaceutical industry: food, pharmaceutical

- conveying of dry foods e.g. rice, cereals, sugar, milk powder, powders, coffee, tea, grains, flour, frozen foods

- mixer, dryer, packaging machine, bulk-bag (big bag)-charging and discharging, mill

- bellows, compensators

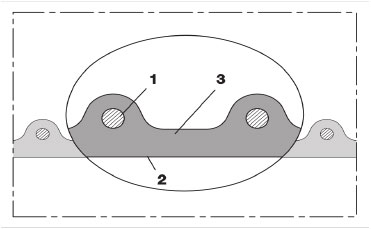

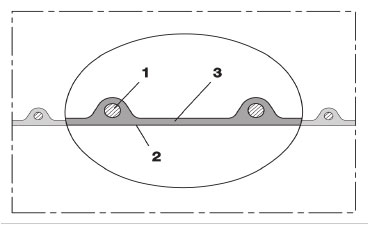

Design, material:

CP construction

- clamp profile supporting spiral: galvanized steel

- wall: special premium ether-polyurethane (Pre-PUR®)

Temperature Range:

- -40°F to 195°F

short time to 255°F

Properties:

- abrasion protection via external clamp profile

- secure clamping of the wall within the clamp profile

- highly flexible + compressible 5:1

- abrasion-resistant

- Food grade wall, complies with: EU-Directive 10/2011 and EC 1935/2004, incl. the latest EU-Directive 2015/174, FDA 21 CFR 177.2600

- odorless and tasteless

- microbe and hydrolysis resistant

- good resistance to oil, gasoline, and chemicals

- very good low temperature flexibility

- manufacturing process acc. GMP EC 2023/2006

- conforms to RoHS guideline

AIRDUC® PUR 350 FOOD-AS

Antistatic food hose and pharmaceutical hose, medium-heavy duty

Applications:

- flexible hose/ ducting for abrasive powder, bulk material, granulate and for gases

- food industry, pharmaceutical industry: food, pharmaceutical

- conveying of dry foods e.g. rice, cereals, sugar, milk powder, powders, coffee, tea, grains, flour, frozen foods

- mixer, dryer, packaging machine, bulk-bag (big bag)-charging and discharging, mill

- explosion hazard area

- clean room ventilation, semiconductor production machine

- paper mill, paper and pulp industry: waste water, air extraction

- medical device/ medical technology, healthcare sector: cable protection conduit, air supply hose, extraction hose

- municipal vehicle: lawn mower, slope mower, leaf blower/ leaf collector

Design, material:

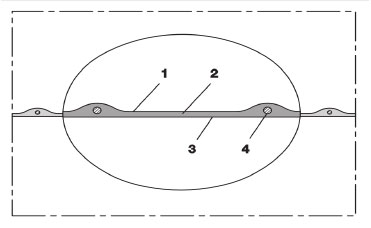

AIRDUC® profile hose

- spring steel wire firmly embedded in the wall

- wall: permanently antistatic premium ether-polyurethane (Pre-PUR®)

- wall thickness 0.03 inch approximate

Temperature Range:

- -40°F to 195°F

short time to 255°F

Properties:

- medium-heavy duty

- highly abrasion resistant

- Food grade wall, complies with: EU-Directive 10/2011 and EC 1935/2004, incl. the latest EU-Directive 2015/174, FDA 21 CFR 177.2600

- odorless and tasteless

- microbe and hydrolysis resistant

- good resistance to oil, gasoline, and chemicals

- very good low temperature flexibility

- permanently antistatic wall: in accordance with ISO 8031 electrical and surface resistance <10⁹ Ω and in accordance with TRGS 727 <2,5*10⁸Ω

- in accordance with ATEX 2014/34/EU (1999/92/EC) and German TRGS 727: pneumatic transport of flammable dusts and bulk materials (Zone 20, 21, 22 inside), aspiration of combustible dusts (Zone 22 inside), for conveying for flammable liquids (inside zone 0, 1, 2), for conveying for non-flammable liquids, for use in zone 1 and 2 (gases), for use in zone 0 (gases)

- according to DIN 26057 Type 2

- manufacturing process acc. GMP EC 2023/2006

- manufacturing process acc. GMP EC 2023/2006

- conforms to RoHS guideline

AIRDUC® PUR 351 FOOD

Food hose and pharmaceutical hose, medium-heavy duty and reinforced

Applications:

- flexible hose/ ducting for abrasive powder, bulk material, granulate and for gases

- food industry, pharmaceutical industry: food, pharmaceutical

- conveying of dry foods e.g. rice, cereals, sugar, milk powder, powders, coffee, tea, grains, flour, frozen foods

- vacuum conveying device, vacuum hopper, suction conveyor, dosing system

- mixer, dryer, packaging machine, bulk-bag (big bag)-charging and discharging, mill

- industrial vacuum cleaners, vacuum cleaners

Design, material:

AIRDUC® profile hose

- spring steel wire firmly embedded in the wall

- wall: special premium ether-polyurethane (Pre-PUR®)

- wall thickness 0.04 inch approximate

Temperature Range:

- -40°F to 195°F

short time to 255°F

Properties:

- medium-heavy duty

- highly abrasion resistant

- Approved by an independent testing laboratory for the complete hose acc. to EU-Directive 10/2011 and EC 1935/2004 and the latest EU-Directive 2015/174, food grade polyurethane, complies with: FDA 21 CFR 177.2600 and 178.2010

- Approval acc. to EU-Directive 10/2011 (food simulants A, B, C or E and D2) and EC 1935/2004

- odorless and tasteless

- microbe and hydrolysis resistant

- good resistance to oil, gasoline, and chemicals

- very good low temperature flexibility

- flame-retardant according to: UL94-HB

- manufacturing process acc. GMP EC 2023/2006

- conforms to RoHS guideline